The simple-looking lens on your spectacle frame is, in fact, a very complex and interlayered package, which addresses your visual and physiological needs. Coatings (or surface treatments) play a huge role in this and are absolutely core to the performance of your lens.

The simple-looking lens on your spectacle frame is, in fact, a very complex and interlayered package, which addresses your visual and physiological needs. Coatings (or surface treatments) play a huge role in this and are absolutely core to the performance of your lens.

Coatings, or in other words, surface treatments are hardly something most would associate with the lens on their spectacle frame. You would probably associate it with some aspects of your car or your electronic gizmo. However, these coatings play a huge role in how an optical lens performs.

And for those of you who thought that the objective of a lens was just to provide refractive correction, it’s time to reassess what a lens actually does!

Lot of technology goes into the making of a lens, which may not seem obvious. However, when you compare, it’s the same technology that sits on top of the camera lenses that get you images on your television (remember the last time you watched the slow motion replays in Animal Planet) or the still images of the surface of the moon. Your mobile phone too uses the same technology while capturing those megapixels!

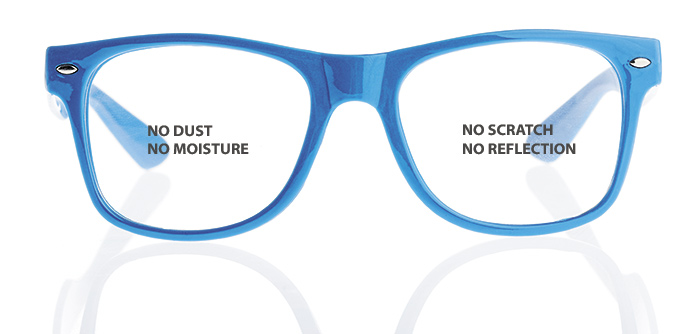

Now, your visual clarity has many foes — glare, smudge, dust, scratch, water, fog, etc, which cause unwanted reflection of light and are responsible for its absorption, diffusion, dispersion or diffraction by the lens’ front-surface, back-surface or their inner material space in-between.

Companies like Rodenstock, Hoya and Essilor, etc, have been investing in R&D to come out with continuous improvements in these areas. This has resulted in some disruptive innovations in terms of optical design and materials, and different surface treatments. A good thing about these treatments, like anti-reflective and smudge-resistant coatings, is that consumers can appreciate their benefits quickly, when comparing it with the technology of the past.

TYPES OF COATINGS

On a technical level, these coatings number to quite a few layers. The more obvious coatings that your optician will inform you about, would be the treatments that have anti reflective (or anti glare), anti-scratch, anti-smudge and the recent anti-fog, properties added to your lens.

Offering a reflection-free lens is the primary objective of multilayer coatings. Natural reflections are caused by the lens’ front-surface or internally from its back-surface. These create unwanted mirror effects and limit the intensity of light transmitted to the wearer’s eyes. Further, there’s the problem of glare that can also be caused by reflections on the lens’ back-surface (when the light source is located behind the wearer), which will alter visual contrast. It could also cause double internal reflections, which create disturbing visual echoes.

Premium anti-reflective coatings today limit reflected light to 1 percent or less. Anti-glare coatings aim to restrict reflected rays for their different wavelengths, and cancel them out. And today’s premium anti-reflective coatings are way less sensitive to scratch or smudge, whilst being very durable.

The anti reflective coating require other layers of coating to ensure this durability, like the he anti-scratch function. The latter requires a surface that is both hard and flexible, in order to resist any types of physical aggressions. Nanocomposite materials today bring this double property, as being both mineral and organic, and also ensure a perfect continuity between the lens’ organic material and the mineral anti-reflective layers.

Many highly sophisticated technologies are hiding behind the perfect transparency of premium lenses. In some case, anti-static layers have been added to anti-reflective stacks, using the same technology that are used in the chambers where electronic integrated circuits are manufactured.

In fact, wiping a lens charges its surface with negative ions will attract positively charged dust particles, thus making it difficult to have perfectly clean lenses. The anti-static properties of premium anti-reflective coatings avoid these negative charging, and particle attraction, making the lens virtually dust-free.

In regions like the Middle East, wearers often experience another vision enemy — fog. It can appear on the lens when moving from air-conditioned places to hotter humid environments. But combining hydrophilic (to avoid fog) and hydrophobic (to repel dust) lens coating features is a tough technical challenge, since they have antagonistic properties. This had often led optical professionals and customers to make compromises.

Nanotechnologies may be the technological breakthrough expected to bring solutions with high-performance and durable anti-fog features, while preserving high dust-free levels. And some promising solutions have already arrived in the market.

REFLECTED HUES

The efficiency of the surface treatments is not only directly linked to the number of layers, but also to the way they are stacked for perfect interaction. Premium multi-layer coatings reduce, to a very low intensity, the chromatic effect due to residual reflections. The coating reflection spectrum will define the quantity of reflected light remaining and its residual colour. Beyond aesthetic criteria, the residual colour can be adapted to eye sensitivity to different colours, yellow-green or blue in particular or potentially ‘achromatic’.

So the next time you ask your optician for a pair of premium lenses, pay as much attention to the product and its features as you would if you were buying that car with all the fancy add-ons or that smartphone with the latest apps. And try to remember that in all these products, the amount of R&D and technology that goes into your lens is probably the same!